Flowmeter

A flowmeter is an instrument used to measure the rate of flow of liquids, gases, or steam in a system. It helps determine how much fluid passes through a pipe or channel over a given time, usually expressed in liters per second, cubic meters per hour, or similar units.

Types of flowmeters include turbine meters, ultrasonic meters, and differential pressure meters, each suited for different applications. They are widely used in industries like water treatment, oil and gas, and chemical processing to ensure efficiency, safety, and accurate resource management.

A flowmeter is an instrument used to measure the quantity of liquid, gas, steam, powder, or a combination of these substances moving through a pipe or open channel. The choice of flow measurement method depends on the application, the type and properties of the medium, and site-specific conditions such as installation environment and accuracy requirements.

We provide a comprehensive range of flowmeters, including Coriolis, electromagnetic, vortex, and variable area flowmeters, designed to deliver precise, reliable measurements across diverse industrial processes.

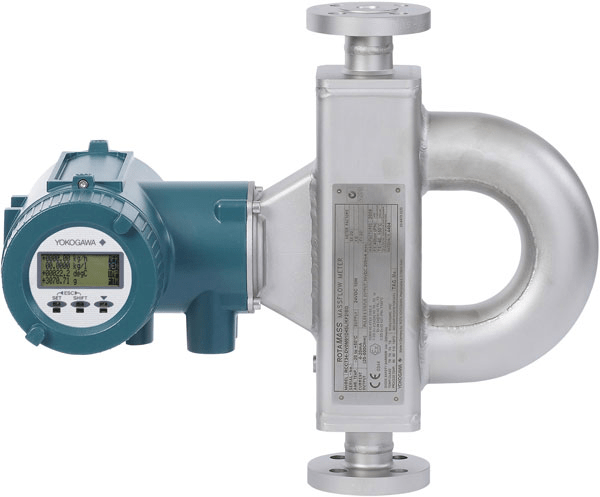

Coriolis Flow Meters

Coriolis meters measure mass flow directly by vibrating one or more tubes; the Coriolis force induced by the flowing fluid is proportional to mass flow. They also provide density (from vibration frequency) and process temperature, giving a true multivariable instrument for liquids and gases.

- Direct mass flow (kg/h, t/h) plus density, temperature, volumetric flow, and totalized flow—no external P/T compensation required.

- High accuracy & turndown: liquids typically to ±0.1% of rate (or better), gases to ±0.5–1% of rate; wide turndown (up to 50:1+).

- Insensitive to fluid properties (viscosity, conductivity, Reynolds number) and excellent on non-conductive and slurry services.

- Bi-directional measurement; no moving parts; minimal maintenance.

- 4–20 mA (HART), pulse/frequency, and digital protocols (Modbus/Fieldbus/Profibus/EtherNet/IP) for easy DCS/PLC integration.

- Hygienic options (Tri-Clamp, polished finishes, CIP/SIP capable); hazardous-area approvals available (Zone/Div).

- Sizes from micro-flow dosing to large line sizes; custody-transfer certified variants available on request.

Magnetic Flowmeters

At Aditi Process Solutions, we supply and integrate electromagnetic (mag) flowmeters tailored to your process—not the other way around. Drawing on decades of field-proven mag-meter technology, we offer flexible configurations for most industrial services, from water & wastewater to chemicals, slurries, and hygienic applications.

- Works on water, wastewater, acids/caustics, brine, slurries, food syrups, and CIP solutions.

- Won’t work on non-conductive fluids (e.g., hydrocarbons, deionized water below the meter’s minimum conductivity) or on gases/steam.

- Typical accuracy ±0.2% of rate (or better) with wide turndown; stable on varying viscosity/density.

- Multivariable electronics: totalized flow, bidirectional measurement, empty-pipe detection, advanced diagnostics.

- 4–20 mA (HART), pulse/frequency, and digital protocols (Modbus/Profibus/EtherNet/IP) for seamless DCS/PLC integration.

- Hygienic designs (Tri-Clamp, polished finishes, CIP/SIP capable); hazardous-area approvals available.

- Available as full-bore inline meters and insertion (hot-tap) versions for large lines and retrofits.

Vortex Flowmeters

Vortex meters measure volumetric flow by detecting the frequency of vortices shed from a bluff body placed in the flow. The shedding frequency is proportional to fluid velocity; with known pipe size, flow is computed. They’re robust, have no moving parts, and excel on steam and clean liquids/gases.

- Great for steam: saturated or superheated; stable accuracy without impulse lines.

- Wide rangeability: typical turndown 20:1–30:1 with good linearity.

- Accuracy (typical): liquids ±0.75–1.0% of rate; gases/steam ±1.0–1.5% of rate (model-dependent).

- Low maintenance: solid-state sensing, no orifice plates to foul; bi-directional measurement.

- Outputs & comms: 4–20 mA (HART), pulse/frequency for totalizing/batching, Modbus/fieldbus options.

- Multivariable options: integrated temperature (and sometimes pressure) for mass flow/energy of steam and compressible gases.

- Construction: wafer or flanged body; high-temperature/high-pressure designs available; hazardous-area approvals on request.

Rotameter – Variable Area Flowmeter

Rotameters are variable-area flowmeters: a float rises in a tapered tube as flow increases. The float position indicates flow rate on a calibrated scale. Simple, reliable, and no external power required—ideal for local indication of liquids or gases.

- Direct visual indication with optional switches (high/low alarms) and transmitters (4–20 mA / pulse) on metal-tube models.

- Wide turndown (typically 10:1); accuracy commonly ±1–2% of full scale (model-dependent).

- Low pressure drop, minimal maintenance, and excellent for small to medium line sizes and purge/bypass duties.

- Body choices: glass-tube (clear sight), metal/armored tube (high pressure/temperature, opaque/dirty fluids), and plastic (cost-effective, non-corrosive duties).

- Float materials and trims for corrosion/cleanliness: 316L, Hastelloy®, Titanium, PTFE, etc.

- Process connections: threaded, flanged, Tri-Clamp; valve-integrated purge meters available for precise set-points.

Orifice Plate And Assembly

An orifice assembly is a primary flow element that creates a controlled pressure drop; a DP transmitter then converts this to flow via the square-root relationship. It’s a simple, rugged, and widely standardized solution for liquids, gases, and steam.

What’s in the assembly

Tappings to DP transmitter: impulse lines, 3-/5-valve manifold, isolation valves; condensate pots for steam where required.

Orifice plate: precision, sharp-edged bore; materials: 316/316L, Duplex, Hastelloy®, Monel®, Tantalum cladding, etc.

Carrier / Orifice flanges: raised-face or RTJ with jack screws for easy plate removal; includes pressure taps (typically flange taps).

Gaskets & bolts: selected for temperature/pressure and chemistry.